Returns are expensive and time-consuming, especially for ecommerce businesses handling high volumes. In 2024, returns cost retailers $890 billion, with an average return rate of 16.9%. Manual processes, poor automation, and inefficient systems worsen the problem, leading to slow refunds, lost revenue, and frustrated customers.

Here’s a quick breakdown of the 5 biggest return challenges and how to solve them:

-

Manual Processing Overload: Support teams waste time on repetitive tasks like emails and label generation.

Solution: Use self-service return portals to automate approvals and streamline workflows. -

High Refund Rates: Refunds eat into revenue, especially for issues like sizing.

Solution: Encourage exchanges with automated product recommendations and store credit incentives. -

Inconsistent Approvals: Manual decisions lead to fraud risks and policy loopholes.

Solution: Apply automated approval rules for fairness and fraud prevention. -

Slow Label Generation: Delays in creating return labels slow inventory restocking.

Solution: Automate instant prepaid and QR code label generation. -

Lack of Data Insights: Missing return data prevents process improvements.

Solution: Track return metrics to identify trends and fix recurring issues.

Automation is the key to faster returns, higher customer satisfaction, and better revenue retention.

Returns Management Software Turns Refunds Into Revenue - Here’s How

sbb-itb-a3e286c

Problem 1: Manual Processing Overloads Support Teams

When returns are managed through email, support teams often find themselves drowning in administrative tasks. They have to read through messages, verify orders, and manually process return labels - all of which eats up valuable time and energy. This one-by-one approach lacks a standardized workflow, leading to inconsistencies in policy enforcement and hours wasted on repetitive tasks.

The slow pace of manual processing creates a domino effect. Customers, frustrated by delays, send follow-up emails asking, "Where’s my refund?" These inquiries pile up, further burdening already overwhelmed staff. On top of that, manual data entry increases the likelihood of errors, such as mislabeled shipments, which then require even more time to fix. Instead of tackling more complex customer issues or focusing on strategic goals, support teams are stuck in a cycle of administrative overload.

This inefficiency also impacts data collection. Without a streamlined system, it’s hard to gather insights, like identifying common return reasons or product issues. Studies show processing times can stretch to 10 days per return, leaving returned items in limbo and unavailable for resale. With nearly 17% of sales resulting in returns, manual processes simply can’t keep up.

All of this points to one solution: automation through self-service return portals.

Solution 1: Use Self-Service Return Portals

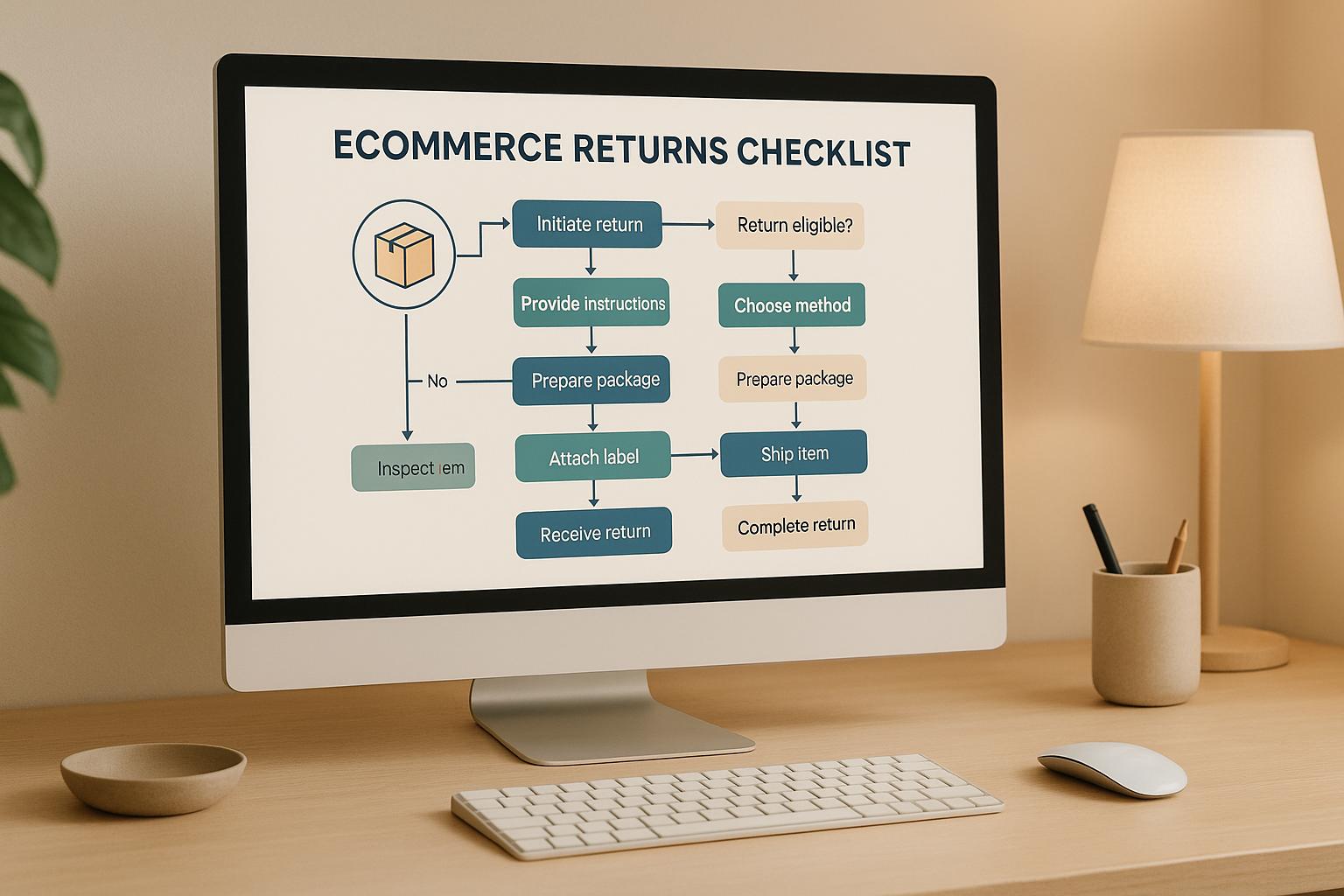

A self-service return portal takes the pressure off your support team by letting customers handle returns themselves. With a portal, customers simply enter their order number and email to access eligible items. They can select what they want to return, provide a reason, and choose how they’d like it resolved - whether that’s a refund, exchange, or store credit. If the return meets your criteria, the system generates a prepaid shipping label instantly.

This setup eliminates much of the initial manual work. Automated approval rules can handle straightforward cases, such as returns under $50 or those within the return window, while flagging higher-value or suspicious requests for manual review. This frees up your team to focus on more complex tasks.

When TechDirect introduced an automated returns portal, they saw impressive results. Processing times dropped from 10 days to just 4 - a 60% improvement - and customer satisfaction scores for "ease of return" jumped by 20%. Items arrived with proper documentation and labels, speeding up restocking and reducing confusion.

"Making returns difficult shouldn't be the goal - there's actually a real opportunity to create loyalty through the return experience." - Alexandria Collis, Director of Operations, Princess Polly

Platforms like Forthroute make implementing a self-service portal easy, especially for Shopify merchants. Customers access the portal through a simple "Start a Return" link in your website footer. The system handles everything: approval rules, shipping label generation via carrier integrations, and automatic inventory updates. No coding is needed - just install the app, set your rules, and let the portal do the heavy lifting. At only $19/month plus carrier rates, it’s a small investment compared to the time and resources saved.

Problem 2: High Refund Rates Reduce Revenue

Refunds hit your bottom line in two ways: they cancel out sales and rack up reverse logistics costs, which can climb as high as 65% of the original sale price. In 2024 alone, $890 billion worth of merchandise was returned, with an average return rate of 17%. To put that into perspective, if your business generates $500,000 in annual sales, a 17% return rate could drain $85,000 in revenue - before you factor in logistics costs.

One major culprit? Sizing issues, which account for 52% of all returns. Many of these cases could have been resolved with exchanges instead of refunds if customers had been offered the right alternatives. For lower-cost items, the situation is even trickier - return costs can exceed the product's value. Some businesses now resort to "returnless refunds", letting customers keep the product while refunding their money, simply because it's cheaper than processing a physical return.

But making returns harder isn’t the answer. A better approach is to steer customers toward exchanges or store credit before they hit the refund button. This strategy helps safeguard your revenue while maintaining a positive customer experience.

Solution 2: Prioritize Exchanges with Smart Product Recommendations

The key to protecting revenue lies in making exchanges the easiest and most appealing option. When a customer initiates a return, automated systems can step in to suggest alternatives based on the reason for the return. For example, if the customer says the item is "too small", the system can instantly recommend the next size up. If they say "didn't match the image", it could suggest a similar product with better reviews or more accurate photos. Essentially, it replicates the kind of assistance customers would get in a physical store.

Automation is what makes this scalable. Instead of manually reviewing each return request, a smart return system can handle it automatically. Tools like Forthroute already do this. For instance, when a customer selects "Too small" as the return reason, the system immediately displays other sizes or similar items from your inventory.

Incentives can also encourage exchanges. Offering store credit with a small bonus - say, an extra 10% if used within 24 hours - entices customers to shop again instead of taking their money elsewhere. This not only keeps funds in your business but often leads to higher-value purchases.

The results speak for themselves. In 2025, Gunner Kennels used Shopify's AR toolkit to introduce 3D product models, allowing customers to virtually check if their dog crates would fit before buying. According to Macey Benton, their VP of Marketing, this led to a 5% drop in return and exchange rates as more customers made informed choices upfront.

"As we see higher adoption rates with the models, we are also seeing lower return and exchange rates." - Macey Benton, VP of Marketing, Gunner Kennels

This same idea works during the return process. By asking customers how they intended to use the product and analyzing their responses, you can recommend better-suited alternatives. Not only does this convert refund requests into exchanges, but it also strengthens customer loyalty by showing that you’re invested in meeting their needs.

Problem 3: Inconsistent Approvals Create Fraud Exposure

In addition to slowing down operations, inconsistent manual approvals can leave businesses vulnerable to fraud. When return requests are reviewed manually, decisions can vary widely. For instance, one team member might approve a return for a final sale item because the customer was polite, while another denies the same request. Without clear, uniform guidelines, these inconsistent outcomes can lead to accusations of favoritism or policy bending. Even more concerning, they create opportunities for fraud.

The statistics are alarming: retailers lost $101 billion to return abuse and fraud in 2024. Manual systems lack the tools to catch repeat offenders or recognize patterns of misuse in real time. High return volumes make it nearly impossible to manually verify tags, keep track of frequent returners, or enforce policies like final sale restrictions.

Even honest mistakes, such as data entry errors or mislabeled shipments, can compound these issues. These errors make it harder to maintain visibility into the returns process and identify where problems are occurring.

Customers feel the effects too. When return policies - like deadlines, costs, or conditions - are applied inconsistently, disputes and delays become inevitable. Bad actors often exploit these gray areas, testing the system to see how much they can get away with. These challenges highlight the need for a more dependable, automated solution.

Solution 3: Apply Automated Approval Rules

Automated approval rules provide a reliable and efficient way to handle return requests. By applying consistent "if/then" logic, these systems ensure every decision is made fairly and instantly. For example: "If item is marked Final Sale, then block return" or "If return request is within 30 days and item value is under $50, then auto-approve".

This strategy safeguards your business against fraud. Automation can detect repeat offenders and block new orders from customers with a history of policy abuse. It can also flag high-risk returns, like expensive items, for manual review while allowing low-risk cases to proceed without delay. Tools like Forthroute simplify this process, enabling you to set up rules such as "Auto-approve returns under $50" or "Reject items marked Final Sale" without requiring manual intervention from your support team.

The benefits are clear. For example, TechDirect, a U.S.-based electronics retailer, cut its return processing time from 10 days to just 4 days by switching from manual reviews to an automated returns portal. Beyond fraud prevention, automation speeds up the entire returns process, helping you quickly resell returned merchandise and improve overall efficiency.

Problem 4: Slow Label Generation Delays Inventory Restocking

When label generation is slow, it creates a bottleneck in reverse logistics. A label scan is crucial to update tracking, inventory, and refunds, but manual processes often drag this out unnecessarily. Customers typically have to email support, wait for a response, and then print the label before shipping their return. This entire process leaves products stuck in "limbo", unable to re-enter the inventory system or generate revenue again.

The financial downside here is hard to ignore. Products lose about 1-2% of their value for every week spent in return processing. For a business managing $10 million in annual returns, reducing processing time from 14 days to just 5 days could unlock $480,000 in working capital for every 10,000 returns processed. On top of that, delayed returns create "phantom inventory", where the system shows stock that isn’t actually sellable. This misalignment can trigger failed transactions, particularly for AI-driven shopping agents and automated purchasing tools, which directly hurts conversion rates.

These delays also lead to missed sales opportunities. For instance, a product with a 25% return rate and a two-week processing time ends up causing 3.5 days of lost sales because the inventory is tied up in reverse logistics. On platforms like Amazon, slow return cycles can be even more damaging. Products that go out of stock due to delayed restocking can lose 30-50% of their organic ranking in just 7 days. As Cahoot succinctly puts it: "Restocking speed is the new KPI".

And then there’s the customer experience. Nearly 70% of online shoppers review a brand’s return policy before making a purchase. Convenience ranks as the second most important factor influencing their decision, right after price. When customers face hurdles like waiting for a label, they’re not just less likely to complete the return - they’re also less likely to shop with that brand again.

The solution? Automating label generation to remove these bottlenecks and get inventory flowing again.

Solution 4: Generate Instant Prepaid and QR Code Labels

Automation is the game-changer here. A self-service portal allows customers to generate labels instantly, skipping the need for support team intervention. The moment a return is approved, the system automatically creates a prepaid shipping label and updates tracking in real time. This dramatically accelerates the returns process.

For even greater convenience, printerless QR code returns are a powerful option. Thanks to carrier integrations, customers can receive a QR code on their phone. They simply take their package to a drop-off location like UPS or USPS, where the carrier prints the label for them. With over 200,000 printerless drop-off locations available across the U.S., this eliminates the hassle of needing a home printer. Forthroute supports this feature through its EasyPost integration, enabling customers to show their QR code at drop-off points while the carrier handles the rest.

Automated label generation doesn’t just speed up logistics; it also enhances customer satisfaction. Returns management software can cut processing time by 50% through automated approvals and instant label creation. Some systems can shrink processing times from 14 days to just 48 hours.

"The biggest challenge for reverse logistics is the sheer amount of time it takes to process one return versus shipping out one order. It takes at least two to three times the amount of time." – Brian Lim, Founder and CEO of INTO THE AM

Faster label generation also improves inventory turnover. Quick label scans provide warehouse teams with better visibility into incoming returns, helping them allocate resources more effectively during peak periods. This streamlined process reduces delays and supports overall operational efficiency. Plus, it’s worth noting that 96% of buyers who had an "easy" or "very easy" returns experience said they would shop with that retailer again. The quicker you can turn returned items into sellable stock, the less you’ll spend on carrying costs, which typically range between 20% and 30% of total inventory value.

Problem 5: Missing Data Prevents Process Improvement

When return analytics are missing, it’s nearly impossible to make targeted improvements. Without knowing which products are driving returns, why customers are sending items back, or which SKUs are eating into profits due to high processing costs, businesses are left in the dark. This lack of insight creates a frustrating cycle where recurring problems persist simply because there’s no data to guide solutions.

Take TechDirect, a U.S.-based electronics retailer, as an example. By analyzing return data, they cut their processing time from 10 days to 4 and reduced their 25% monthly return rate. They discovered that 40% of returns were caused by product compatibility issues. Armed with this knowledge, they updated product descriptions and added compatibility checklists, which not only addressed the problem but also boosted their overall sales by 15%.

But the issue isn’t just about identifying problematic products. Without operational metrics like average processing time or weekly return volumes, managers may struggle to spot inefficiencies or allocate resources effectively. SKU-level analysis is particularly important - if you don’t know which items have the highest return rates, you might unknowingly continue investing in products that cost more to process than they generate in revenue.

Customer behavior is another blind spot when analytics are missing. Patterns like "serial returners" or bracketing - where customers order multiple sizes and return most - go unnoticed. Without this information, tailoring policies or marketing strategies to protect your margins becomes a guessing game. Real-time dashboards that track items in transit, pending inspection, or ready for restock can help prevent inventory from sitting idle and ensure stock counts stay accurate. Closing these data gaps is essential for creating efficient, data-driven return processes.

Solution 5: Track Return Metrics and Trends

Addressing these data challenges turns vague return patterns into actionable insights, reducing costs and improving customer satisfaction. Start tracking SKU-level return reasons - like "too small" or "damaged in transit" - to tackle recurring problems. This could mean updating product descriptions, improving packaging, or tightening quality control.

| Data Category | Specific Metrics to Track | Purpose |

|---|---|---|

| Product Performance | Return rate per SKU, return reasons by category | Spot defective or misleading products |

| Operational Efficiency | Average processing time, cost per return | Cut labor and logistics expenses |

| Customer Behavior | Return frequency per customer, bracketing trends | Adjust policies for high-risk customer segments |

| Inventory Health | Restock rate, time-to-resale | Improve stock accuracy and cash flow |

Forthroute’s Professional Plan ($19/month) includes built-in return analytics, offering insights into which products are returned most often and why. For instance, if a particular item consistently gets returned for sizing issues, you can update the product page or consider discontinuing it. Additionally, tracking return shipping costs per SKU allows you to identify items that are unprofitable due to high processing expenses.

When these data insights are paired with automated processes - like those mentioned earlier - return efficiency and revenue retention improve even further. Metrics like processing time and return frequency per customer help identify bottlenecks and fine-tune policies. Real-time dashboards ensure every step of the return process is visible, preventing inventory from piling up in warehouses and keeping stock counts accurate. Together, these efforts support the broader operational improvements discussed throughout this article.

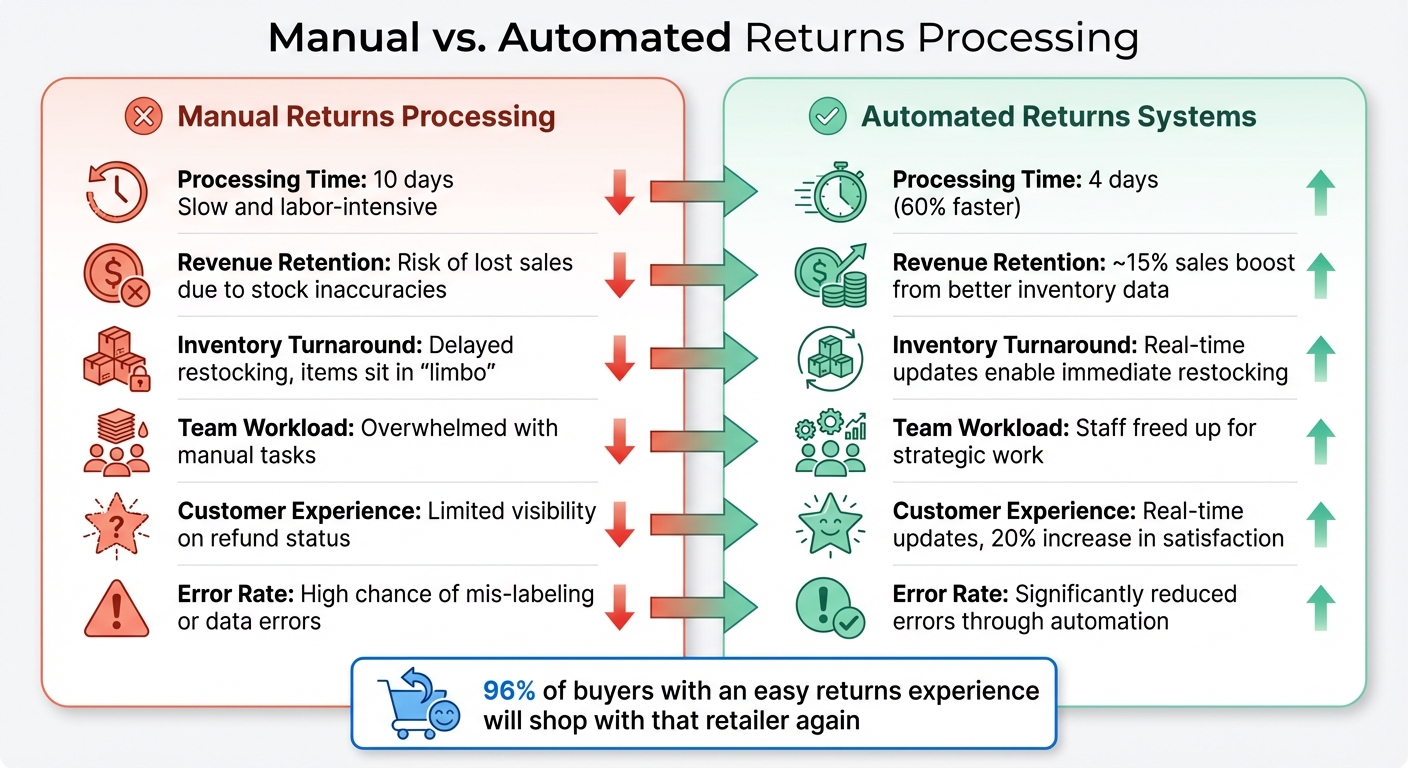

Manual vs. Automated Returns: Side-by-Side Comparison

Manual vs Automated Returns Processing: Key Performance Metrics Comparison

When it comes to handling returns, the difference between manual and automated processes can make or break a retailer's efficiency - especially for businesses managing high volumes. Manual returns take about 10 days to process, while automation cuts that time down to just 4 days. For stores handling hundreds or thousands of returns monthly, that time difference can have a huge impact on customer satisfaction and operational flow.

Manual systems rely on outdated methods like spreadsheets, emails, and manual barcode entries. These processes often create bottlenecks, leaving returned items in "limbo" for days. This not only frustrates customers but also throws inventory accuracy out the window. Automated systems, on the other hand, leverage tools like RFID and Warehouse Management Software (WMS) to handle these issues seamlessly. Dean Jones, Co-founder and CEO of GlamCorner, puts it best:

"Each item has an RFID tag... It just allows clothing to move through rapidly through all the different checkpoints all while keeping the customer informed".

The benefits of automation extend beyond speed. By reducing delays and keeping customers informed, automated systems help build loyalty. A smooth returns process matters - 96% of shoppers who had an easy return experience said they’d shop with the same retailer again.

Comparison Table

| Metric | Manual Returns Processing | Automated Returns Systems |

|---|---|---|

| Processing Time | Approximately 10 days | Approximately 4 days |

| Revenue Retention | Risk of lost sales due to stock inaccuracies | Around a 15% sales boost from better inventory data |

| Inventory Turnaround | Delayed restocking as items sit in "limbo" | Real-time updates enable immediate restocking |

| Team Workload | Overwhelmed with manual tasks | Staff freed up for more strategic work |

| Customer Experience | Limited visibility on refund status | Real-time updates increase satisfaction by 20% |

| Error Rate | High chance of mis-labeling or data errors | Reduced errors through automation |

Conclusion

Handling high-volume returns doesn’t have to drain your resources or eat into your revenue. The challenges discussed in this article can all be tackled effectively with automation.

By swapping out email chains and spreadsheets for a self-service portal, your support team can shift their focus to more strategic tasks. Prioritizing exchanges helps retain revenue while still keeping customers happy. Automated approval rules minimize inconsistent decisions and reduce fraud risks, while instant prepaid or QR code labels speed up inventory turnaround. This is especially critical, considering businesses often allocate 20% to 30% of their total inventory value to carrying stock. Plus, tracking return metrics gives you valuable insights into recurring issues, like sizing problems or inaccurate product descriptions, so you can address them at the source.

Automation doesn’t just solve bottlenecks - it makes the entire process smoother. In fact, 96% of buyers who experience an "easy" or "very easy" returns process say they’d shop with that retailer again. As your business scales, automation grows with you, allowing you to handle more returns without needing to expand your support team or warehouse space.

Turn returns into an opportunity to retain revenue and enhance customer loyalty with Forthroute's automated solution.